Case Study

Case Study

04

04

04

CorroTile Insert Chute

CorroTile Insert Chute

CorroTile Insert Chute

Establishing superiority of CorroTile, lasting over 5 times longer than alternative ceramic liners.

Establishing superiority of CorroTile, lasting over 5 times longer than alternative ceramic liners.

Establishing superiority of CorroTile, lasting over 5 times longer than alternative ceramic liners.

Details

Details

Details

Product

Product

Ceramic Liner

Ceramic Liner

Material Handled

Material Handled

Iron Ore

Iron Ore

Tonnage

Tonnage

Particle Size

Particle Size

Location

Location

Australia

Australia

Application

Application

Transfer Station Insert Chute

Transfer Station Insert Chute

Material Handled

Iron Ore

Tonnage

Particle Size

Location

Australia

Application

Transfer Station Insert Chute

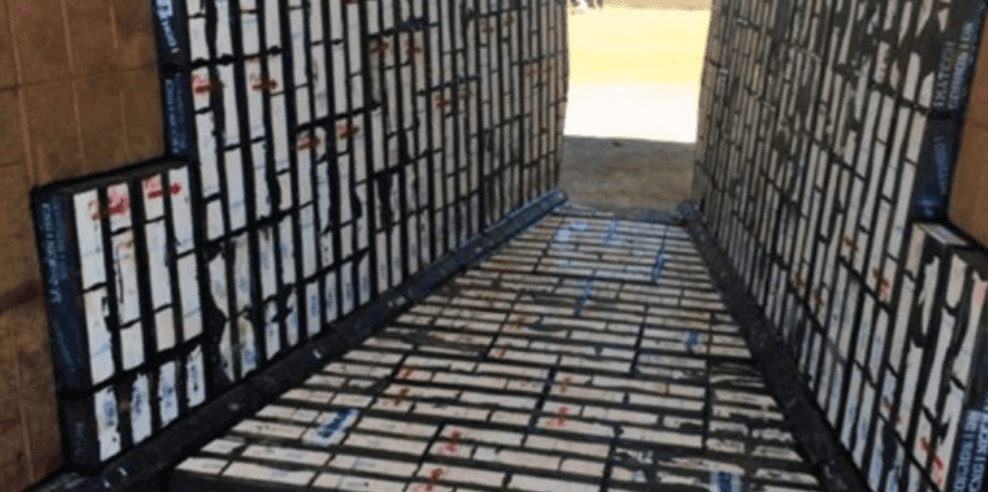

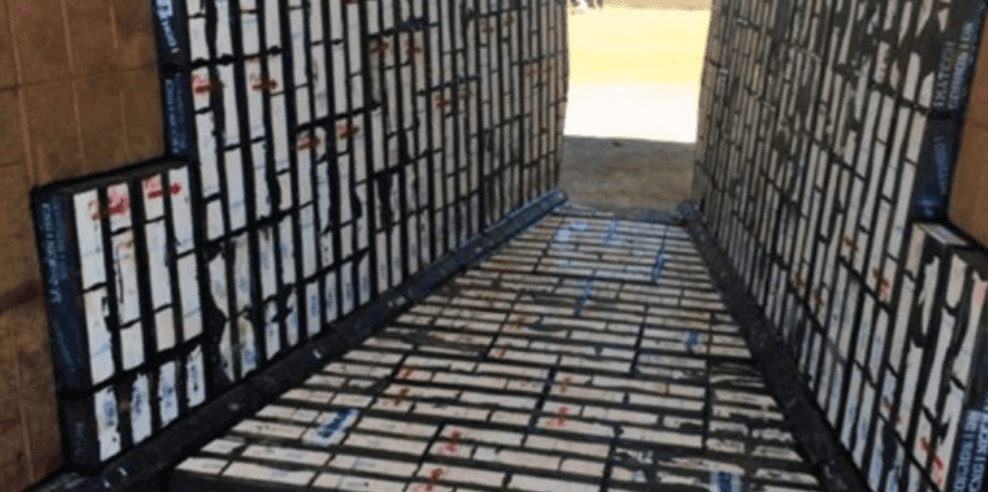

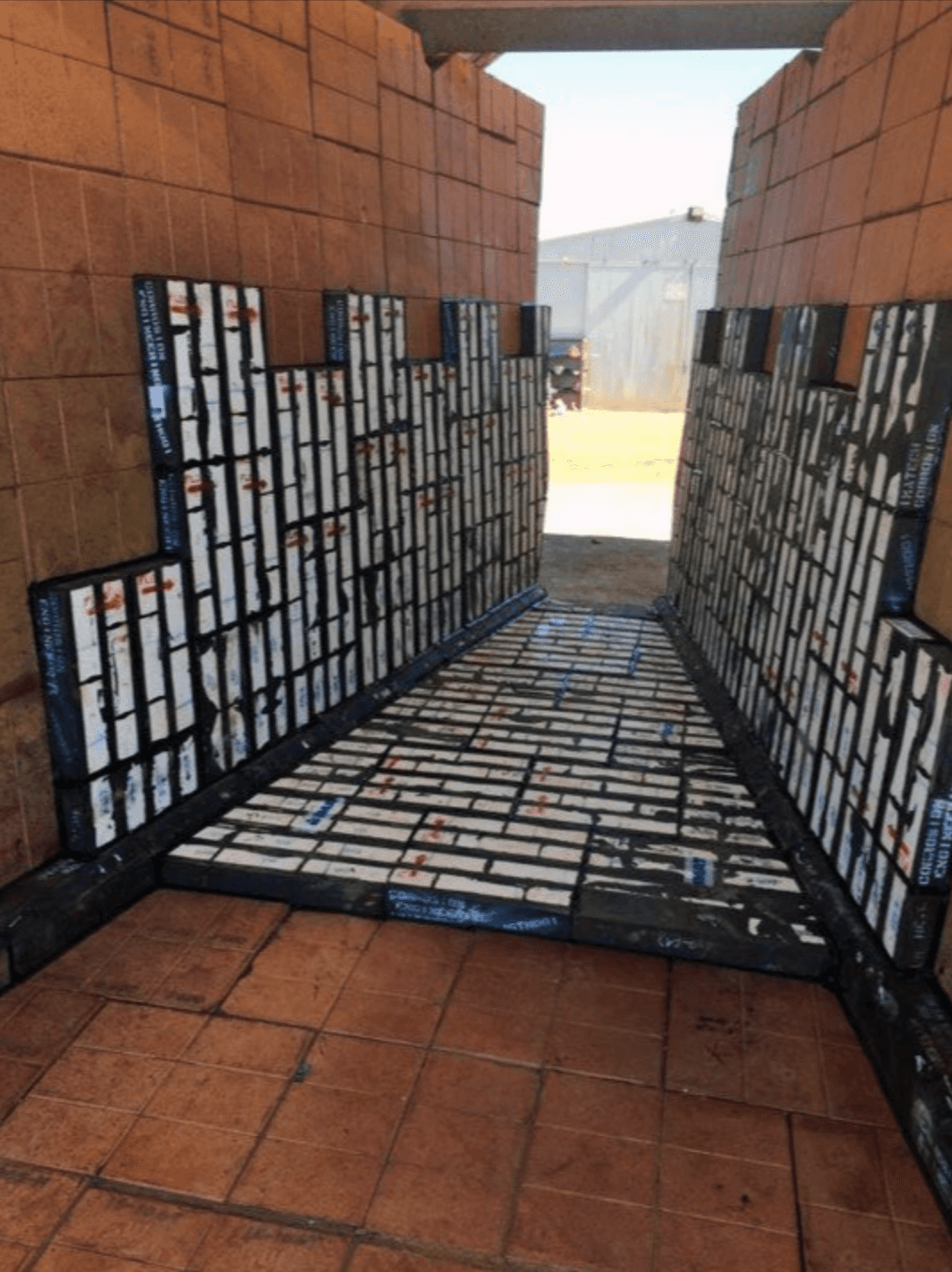

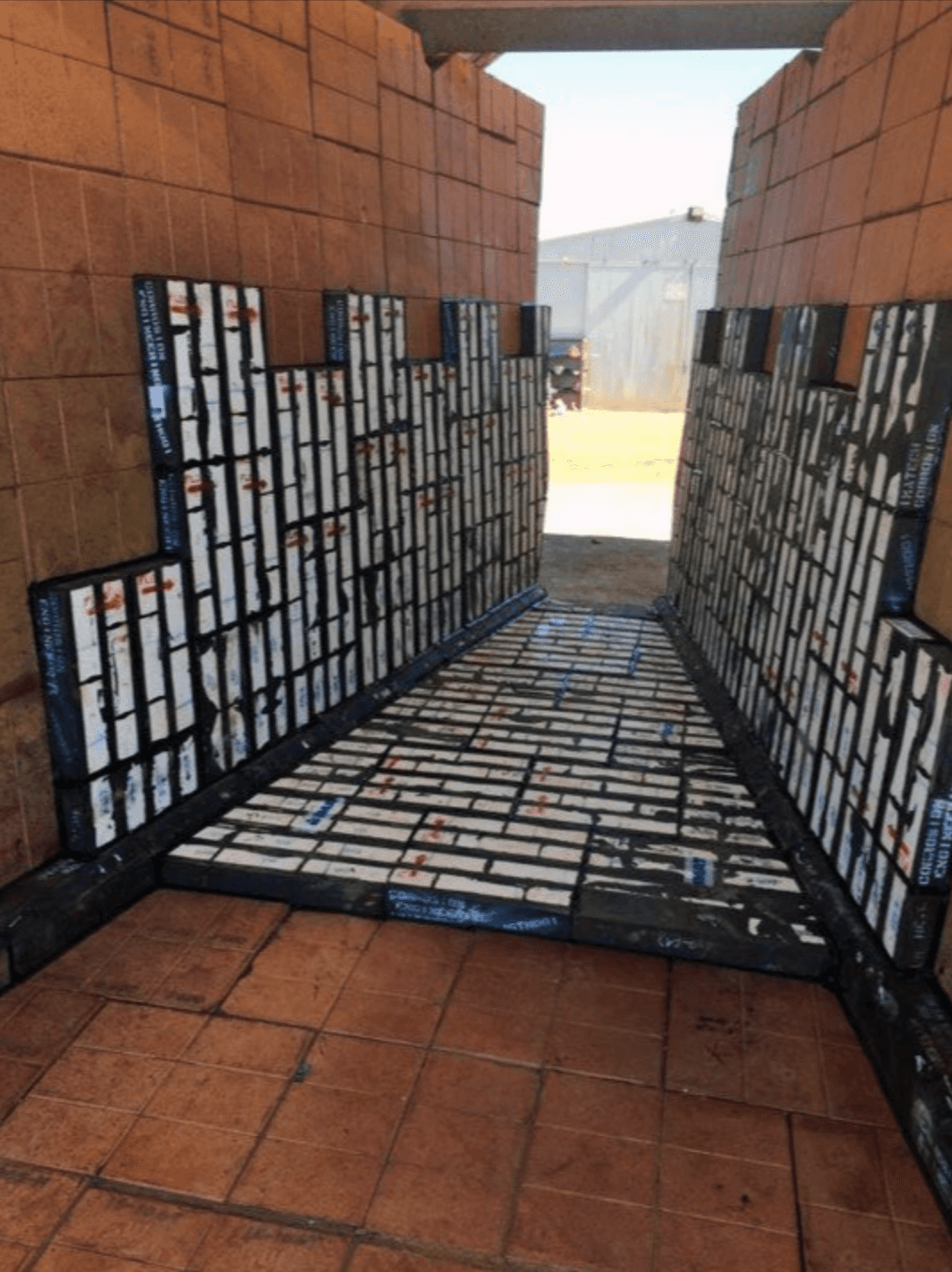

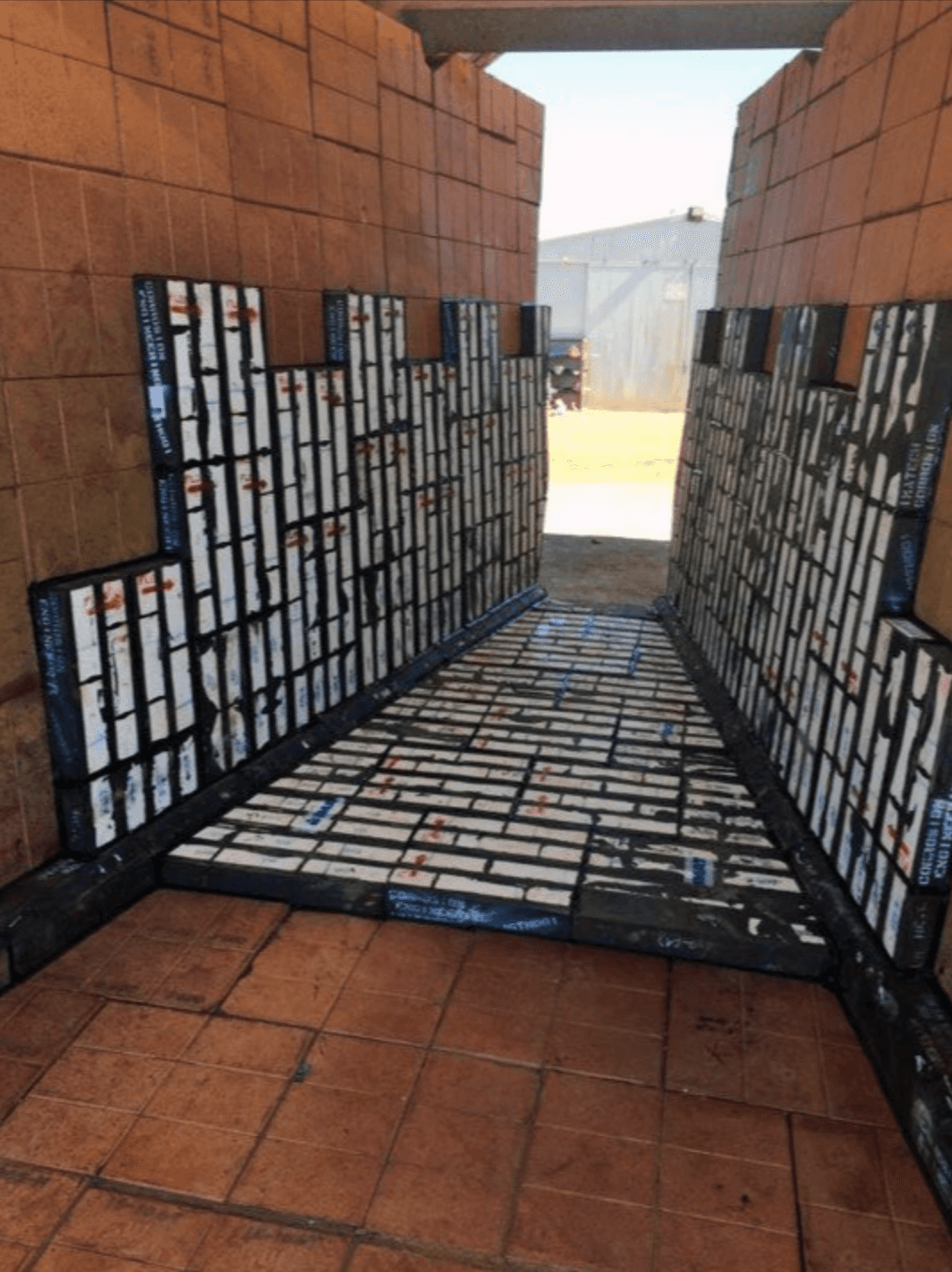

Images

Images

Images

Challenges

Challenges

Challenges

Alternative 63mm ceramic liners in this extremely severe insert chute were lasting less than 6 weeks. The lump and fine iron ore had a drop height of 12 to 13 meters at high velocities. To achieve optimal operating efficiency, the client required a service life of at least 24 weeks.

Alternative 63mm ceramic liners in this extremely severe insert chute were lasting less than 6 weeks. The lump and fine iron ore had a drop height of 12 to 13 meters at high velocities. To achieve optimal operating efficiency, the client required a service life of at least 24 weeks.

Solutions

Solutions

Solutions

With the need for a premium solution, Corrosion Engineering designed and developed a CorroTile wear lining system for the primary wear area of the insert chute using Corrosion Engineering's top performance, proprietary ceramic compound G-Series. The installation took place October of 2015.

With the need for a premium solution, Corrosion Engineering designed and developed a CorroTile wear lining system for the primary wear area of the insert chute using Corrosion Engineering's top performance, proprietary ceramic compound G-Series. The installation took place October of 2015.

Results

Results

Results

After 5 weeks (20th November, 2015), the CorroTile system was in great condition. The majority of alternative liners at this stage would have failed. After 14 weeks in operation (21st January, 2016), an inspection of the CorroTile G-Series showed good operating condition with zero holes, chipping or cracking of the liners or ceramic. The CorroTile lining system lasted 30 weeks in service before being replaced.

Conclusion

Conclusion

Conclusion

This CorroTile lining system proved its superiority in this study, lasting over 5 times longer than alternative ceramic liners. The extremely high performance of CorroTile allowed the client to achieve optimal operational efficiency while also achieving a generous return on investment.

This CorroTile lining system proved its superiority in this study, lasting over 5 times longer than alternative ceramic liners. The extremely high performance of CorroTile allowed the client to achieve optimal operational efficiency while also achieving a generous return on investment.

ready to get started?

Sign up for our Newsletter

ready to

get started?

Sign up for our Newsletter

© Copyright 2024 Corrosion Engineering