Case Study

Case Study

03

03

03

CorroTile Transfer Chute

CorroTile Transfer Chute

CorroTile Transfer Chute

Highly cost-effective with 10 times the wear life of previous liners in a severely abrasive application.

Highly cost-effective with 10 times the wear life of previous liners in a severely abrasive application.

Highly cost-effective with 10 times the wear life of previous liners in a severely abrasive application.

Details

Details

Details

Product

Product

Ceramic Liner

Ceramic Liner

Material Handled

Material Handled

Iorn Ore

Iorn Ore

Tonnage

Tonnage

Particle Size

Particle Size

<35mm

<35mm

Location

Location

Australia

Australia

Application

Application

Transfer Chute

Transfer Chute

Material Handled

Iorn Ore

Tonnage

Particle Size

<35mm

Location

Australia

Application

Transfer Chute

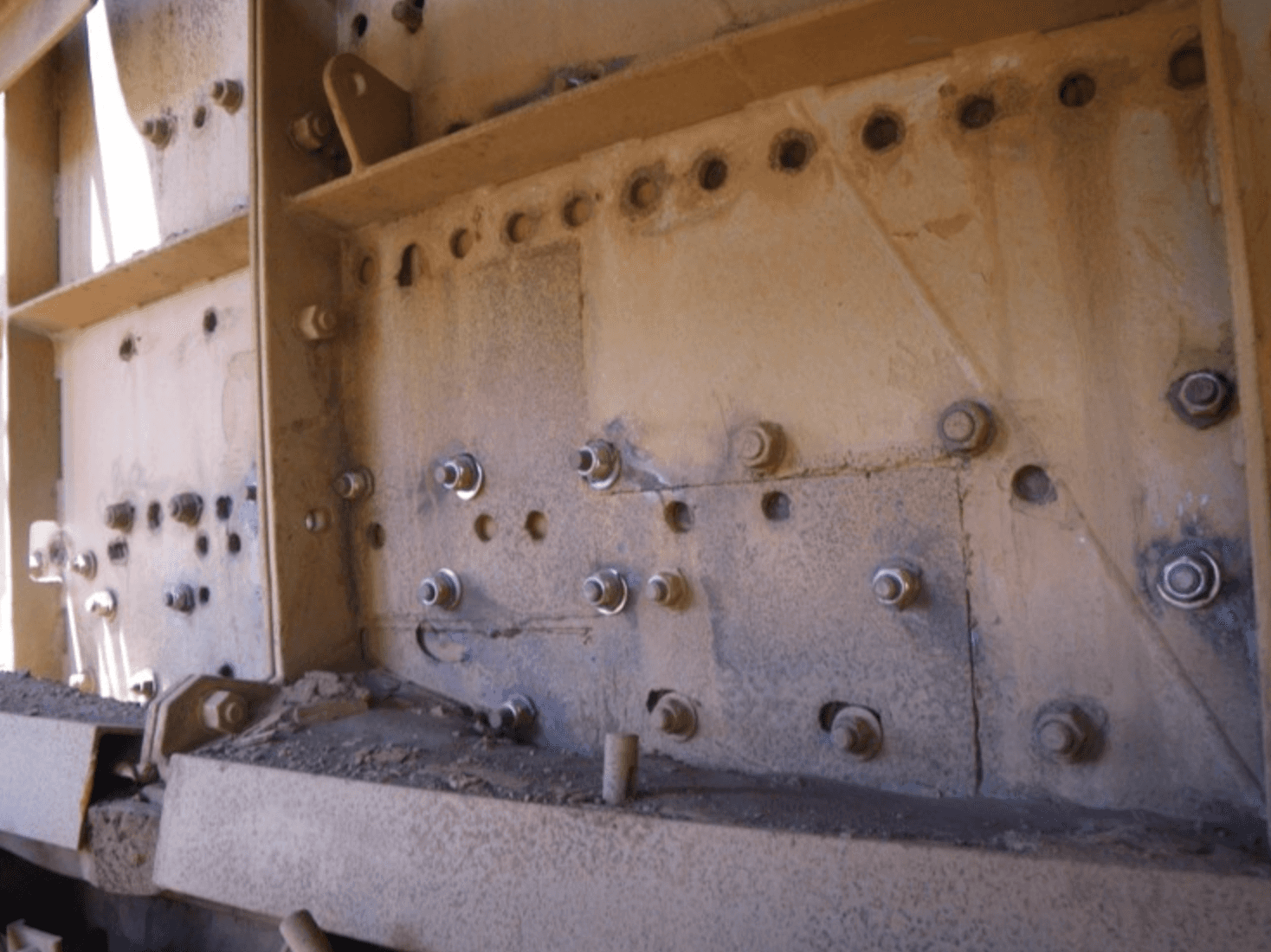

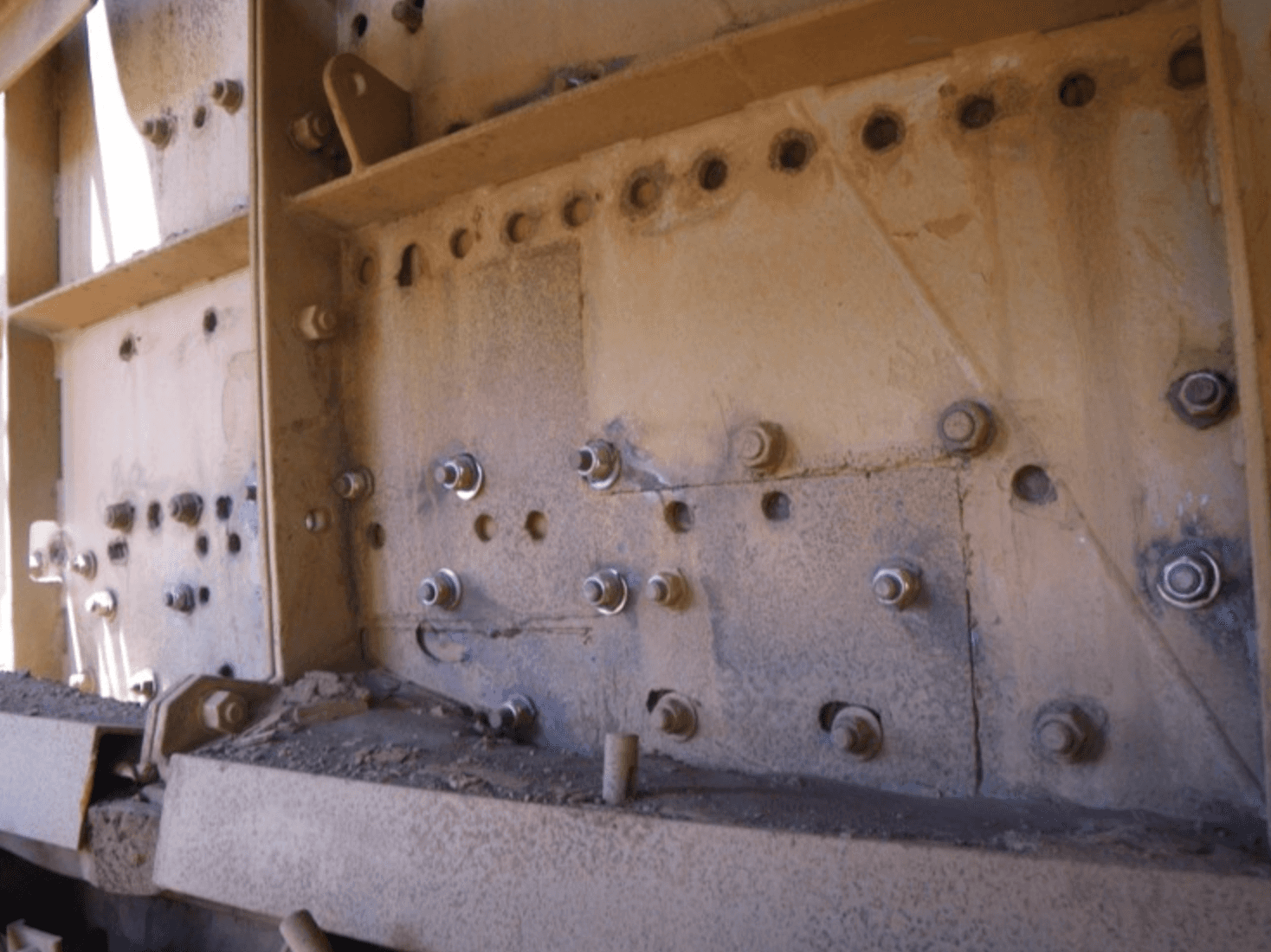

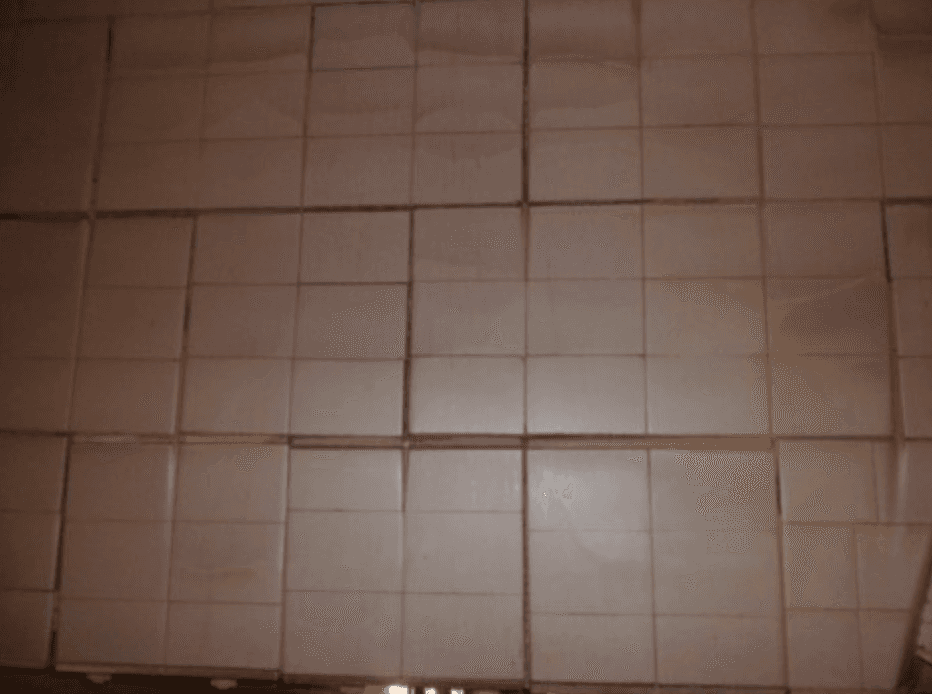

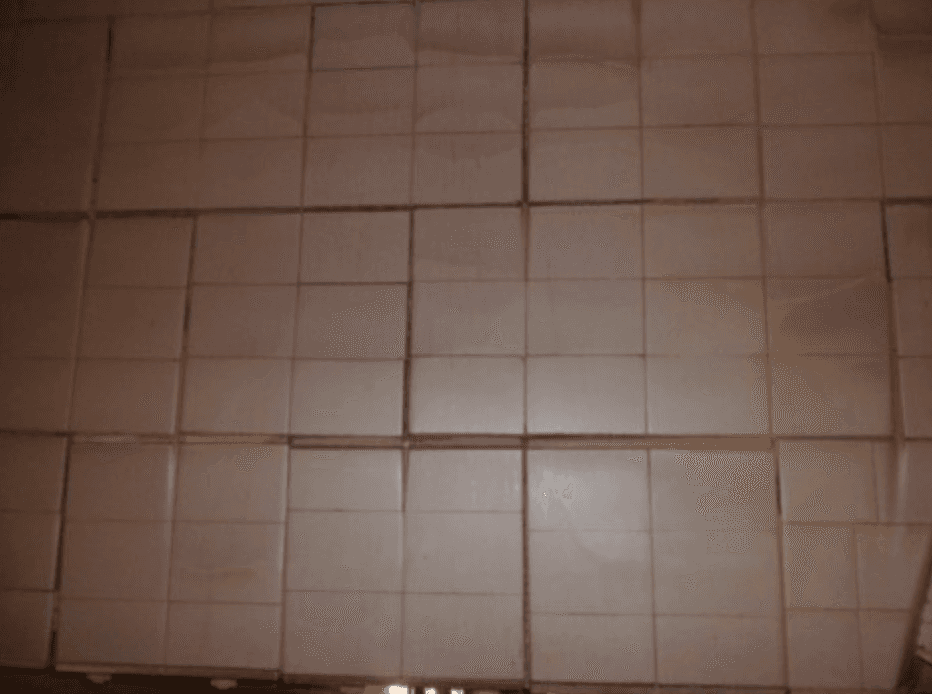

Images

Images

Images

Challenges

Challenges

Challenges

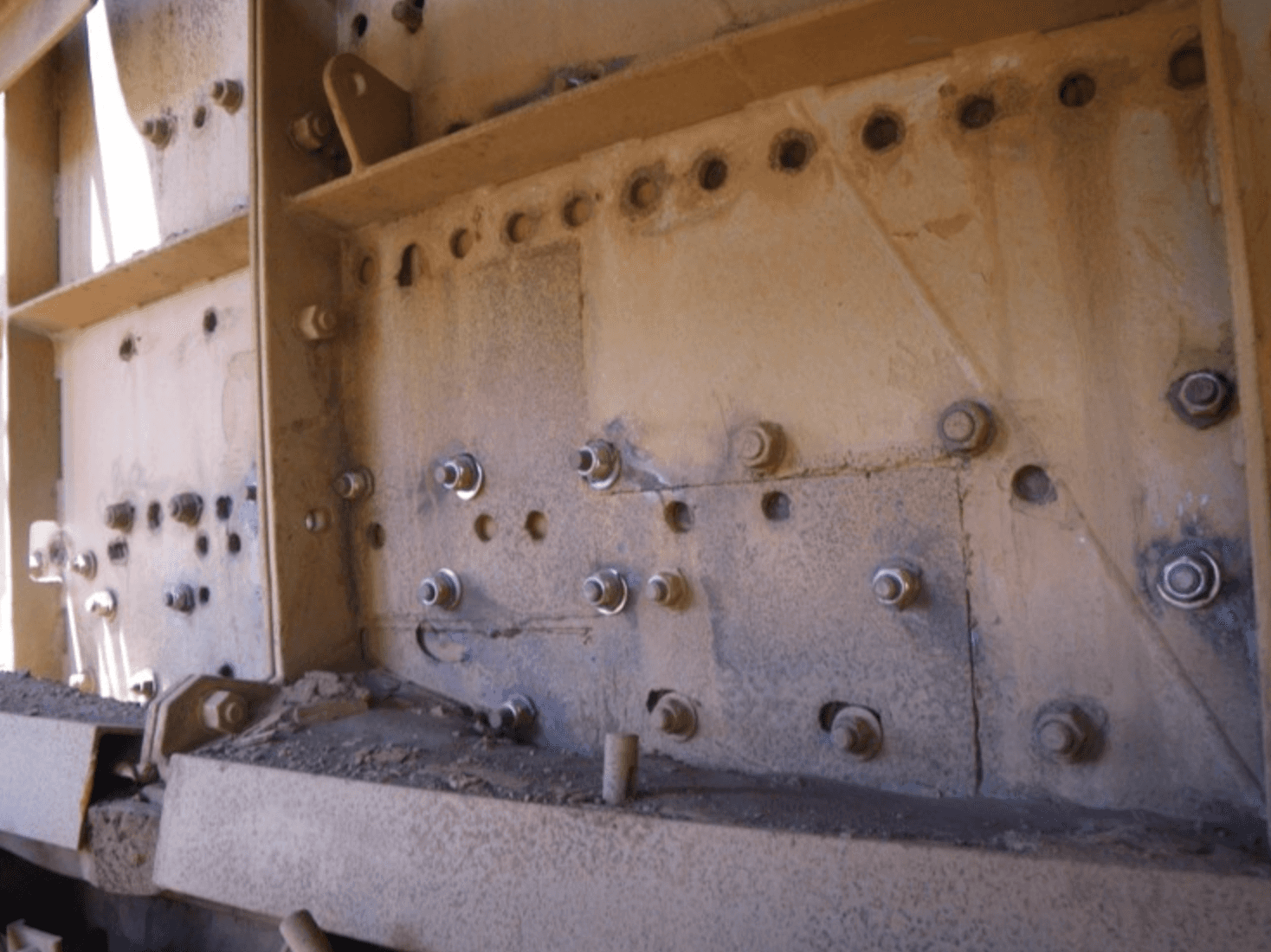

This transfer chute at an iron ore port processing facility was originally lined with metal wear liners. The highly abrasive material wore through these metal liners prematurely and unpredictably, leading to costly production loss as the parent metal began wearing through to cause ore spillage and loss of chute availability. With the use of these alternative metal liners, this transfer chute required maintenance every 4 to 6 weeks.

This transfer chute at an iron ore port processing facility was originally lined with metal wear liners. The highly abrasive material wore through these metal liners prematurely and unpredictably, leading to costly production loss as the parent metal began wearing through to cause ore spillage and loss of chute availability. With the use of these alternative metal liners, this transfer chute required maintenance every 4 to 6 weeks.

Solutions

Solutions

Solutions

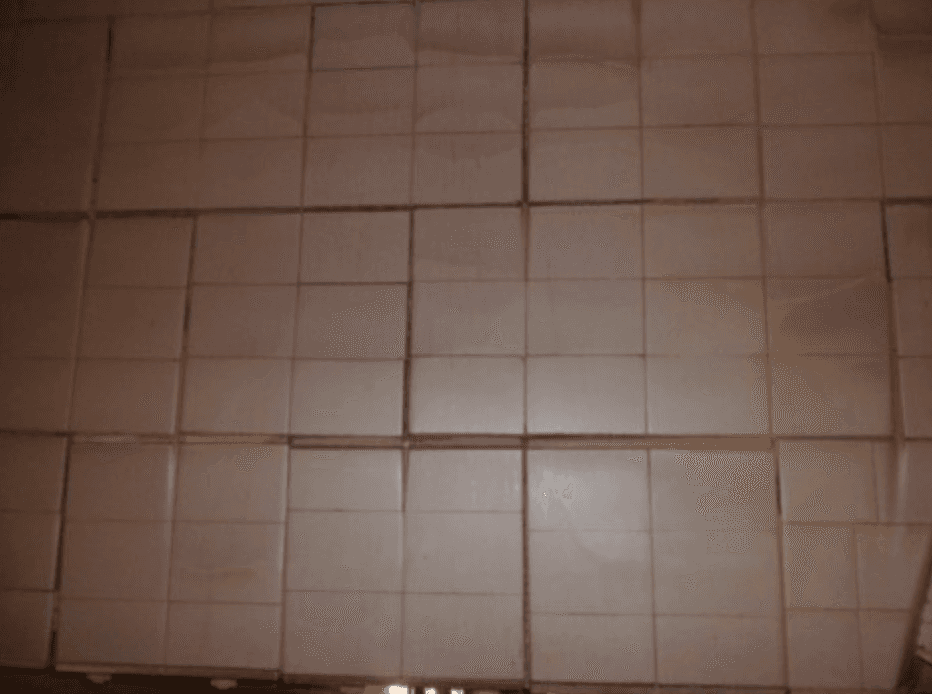

After close consultation with the client, Corrosion Engineering custom-designed and manufactured a CorroTile wear lining system to protect this chute from severe abrasion and wear. This CorroTile system consisted of two types of our proprietary ceramic compounds targeting specific wear areas. CorroTile BLUE was installed throughout the entire chute except for the primary wear areas. Isolated high wear areas in the corners of the transfer chute caused by the side of the ore stream off the impact plate were lined with next generation CorroTile G-Series.

After close consultation with the client, Corrosion Engineering custom-designed and manufactured a CorroTile wear lining system to protect this chute from severe abrasion and wear. This CorroTile system consisted of two types of our proprietary ceramic compounds targeting specific wear areas. CorroTile BLUE was installed throughout the entire chute except for the primary wear areas. Isolated high wear areas in the corners of the transfer chute caused by the side of the ore stream off the impact plate were lined with next generation CorroTile G-Series.

Results

Results

Results

With the use of our custom CorroTile lining system, the client was able to extend the life of this transfer chute from 4 weeks to over 47 weeks and counting without the need to worry about unpredictable wear or production loss.

Conclusion

Conclusion

Conclusion

Our custom CorroTile lining system for this transfer chute proved highly cost-effective, lasting over 10 times the previous wear liners while eliminating maintenance, and increasing profitability.

Our custom CorroTile lining system for this transfer chute proved highly cost-effective, lasting over 10 times the previous wear liners while eliminating maintenance, and increasing profitability.

ready to get started?

Sign up for our Newsletter

ready to

get started?

Sign up for our Newsletter

© Copyright 2024 Corrosion Engineering