Case Study

Case Study

01

01

01

Cyclone Underflow Pipes

Cyclone Underflow Pipes

Cyclone Underflow Pipes

Extreme Cost-Effectiveness with 7 Times the Wear Life of Traditional Lined Piping

Extreme Cost-Effectiveness with 7 Times the Wear Life of Traditional Lined Piping

Extreme Cost-Effectiveness with 7 Times the Wear Life of Traditional Lined Piping

Details

Details

Details

Product

Product

Ceramic Liner

Ceramic Liner

Material Handled

Material Handled

Gold Ore

Gold Ore

Tonnage

Tonnage

Particle Size

Particle Size

<19mm

<19mm

Location

Location

Australia

Australia

Application

Application

Distributor to Ball Mill - Piping

Distributor to Ball Mill - Piping

Material Handled

Gold Ore

Tonnage

Particle Size

<19mm

Location

Australia

Application

Distributor to Ball Mill - Piping

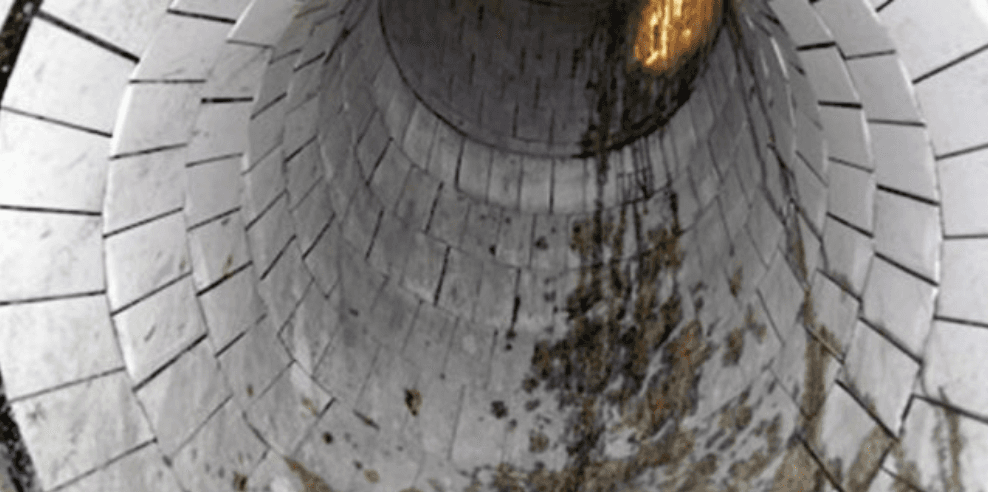

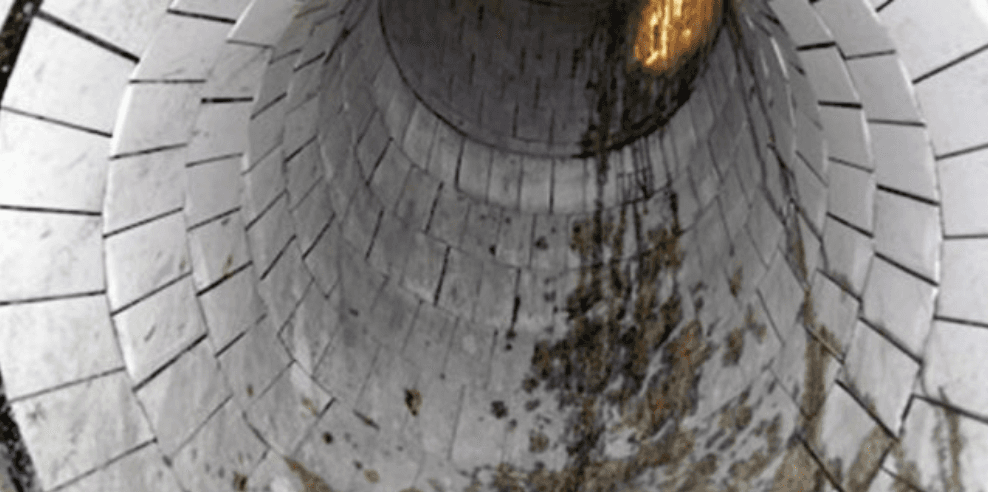

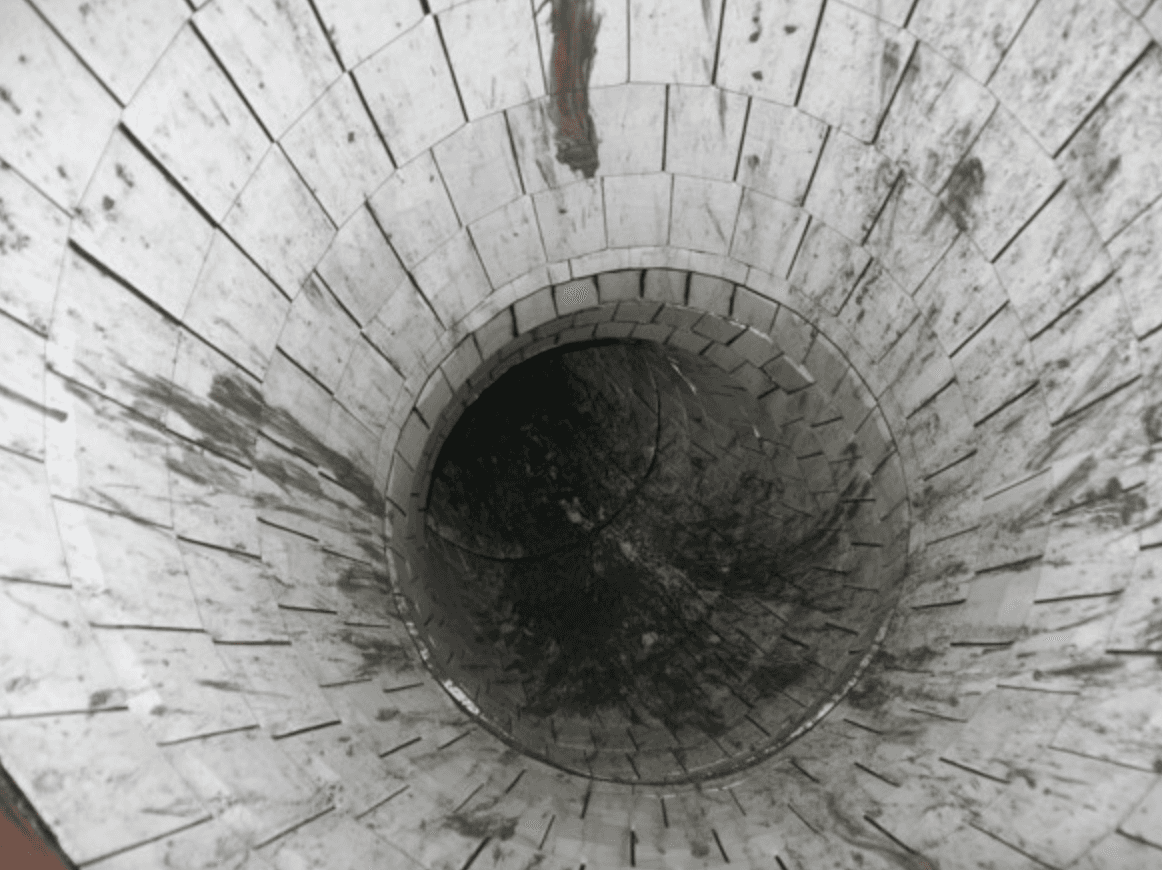

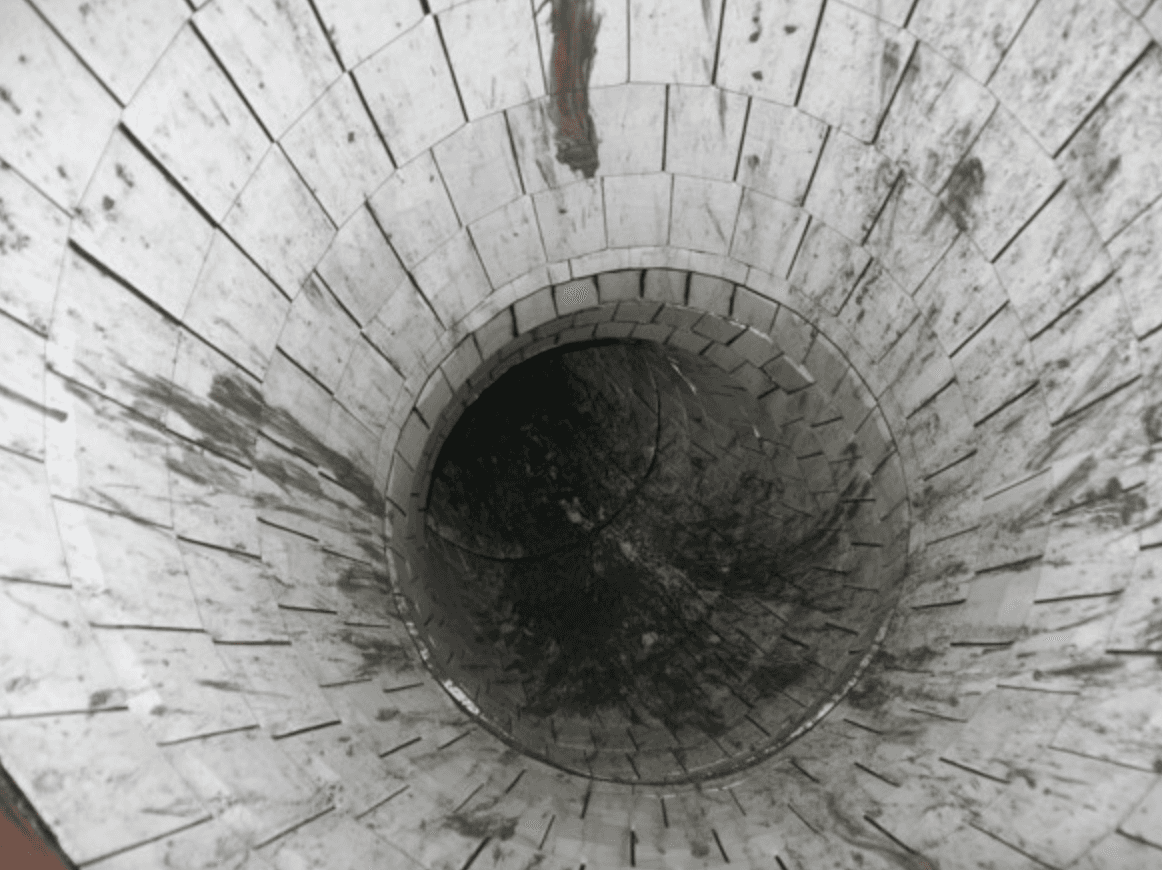

Images

Images

Images

Challenges

Challenges

Challenges

The previous rubber lining wear material needed to be replaced every 13 weeks (lasting only 1 shutdown interval). This was unsatisfactory for the client, who also tried a Ni-Hard wear lining, lasting just 22 weeks. With the highly abrasive material, a next-generation solution needed to be engineered for this pipe to last longer without the need of unscheduled downtime.

The previous rubber lining wear material needed to be replaced every 13 weeks (lasting only 1 shutdown interval). This was unsatisfactory for the client, who also tried a Ni-Hard wear lining, lasting just 22 weeks. With the highly abrasive material, a next-generation solution needed to be engineered for this pipe to last longer without the need of unscheduled downtime.

Solutions

Solutions

Solutions

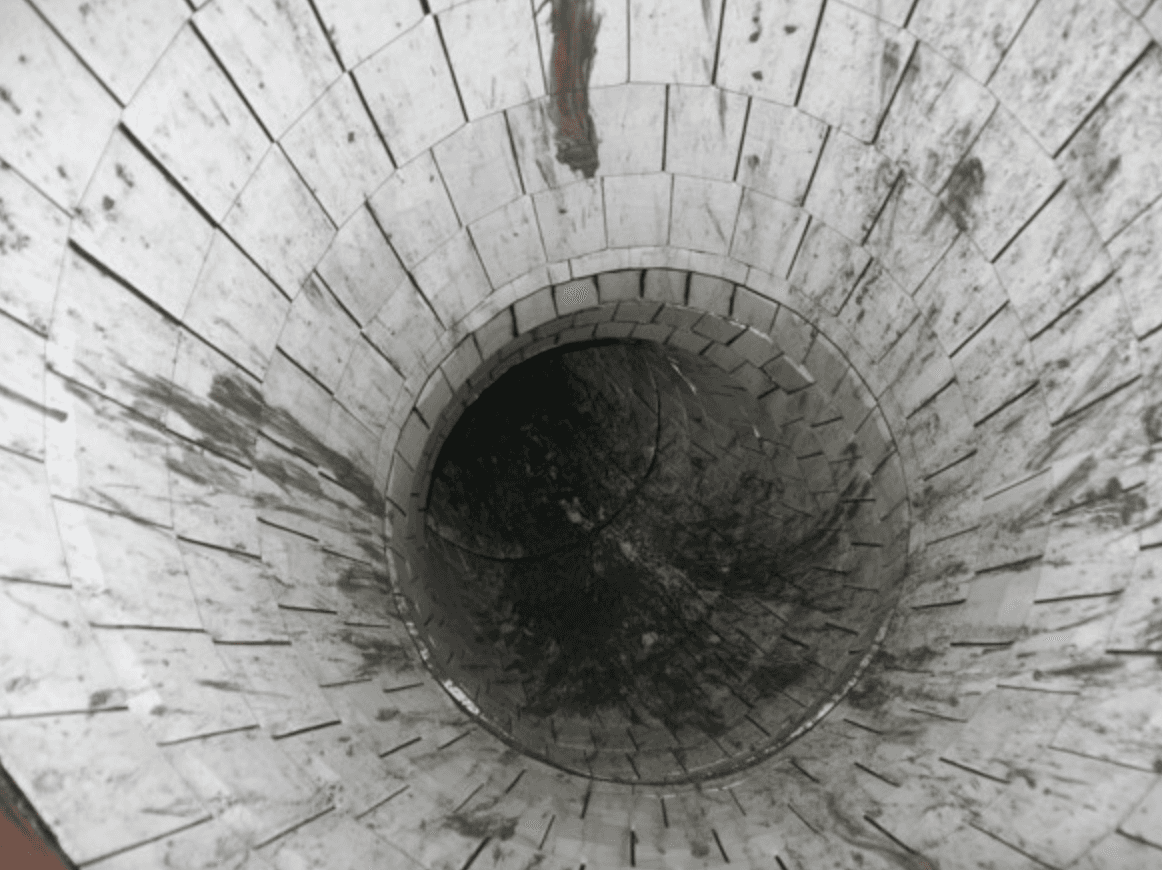

Corrosion Engineering custom-designed and engineered a rubber and ceramic lining to be installed in the pipe with engineered ceramic tile segments bonded in rubber. This lining would be powerful against severe abrasion, wear and chemical attack.

Corrosion Engineering custom-designed and engineered a rubber and ceramic lining to be installed in the pipe with engineered ceramic tile segments bonded in rubber. This lining would be powerful against severe abrasion, wear and chemical attack.

Results

Results

Results

The initial engineered ceramic system was in service for over 78 weeks (lasting over 6 shutdown intervals). Wear studies were conducted and measurements taken from the used pipes indicated that they could've lasted another shutdown, if required.

Conclusion

Conclusion

Conclusion

At present, the replacements are scheduled to occur every 7 shutdowns (91 weeks). This long-lasting solution has proved to be highly cost-effective, with conservative payback at 5 shutdowns and dramatic savings from highly reduced hazardous maintenance.

At present, the replacements are scheduled to occur every 7 shutdowns (91 weeks). This long-lasting solution has proved to be highly cost-effective, with conservative payback at 5 shutdowns and dramatic savings from highly reduced hazardous maintenance.

ready to get started?

Sign up for our Newsletter

ready to

get started?

Sign up for our Newsletter

© Copyright 2024 Corrosion Engineering